Projects

The projects presented here represent a selected subset of those I have led, or am currently leading, as Principal Investigator. They are organised into themes, with some themes having multiple projects. For a comprehensive overview and further information, please refer to my staff page.

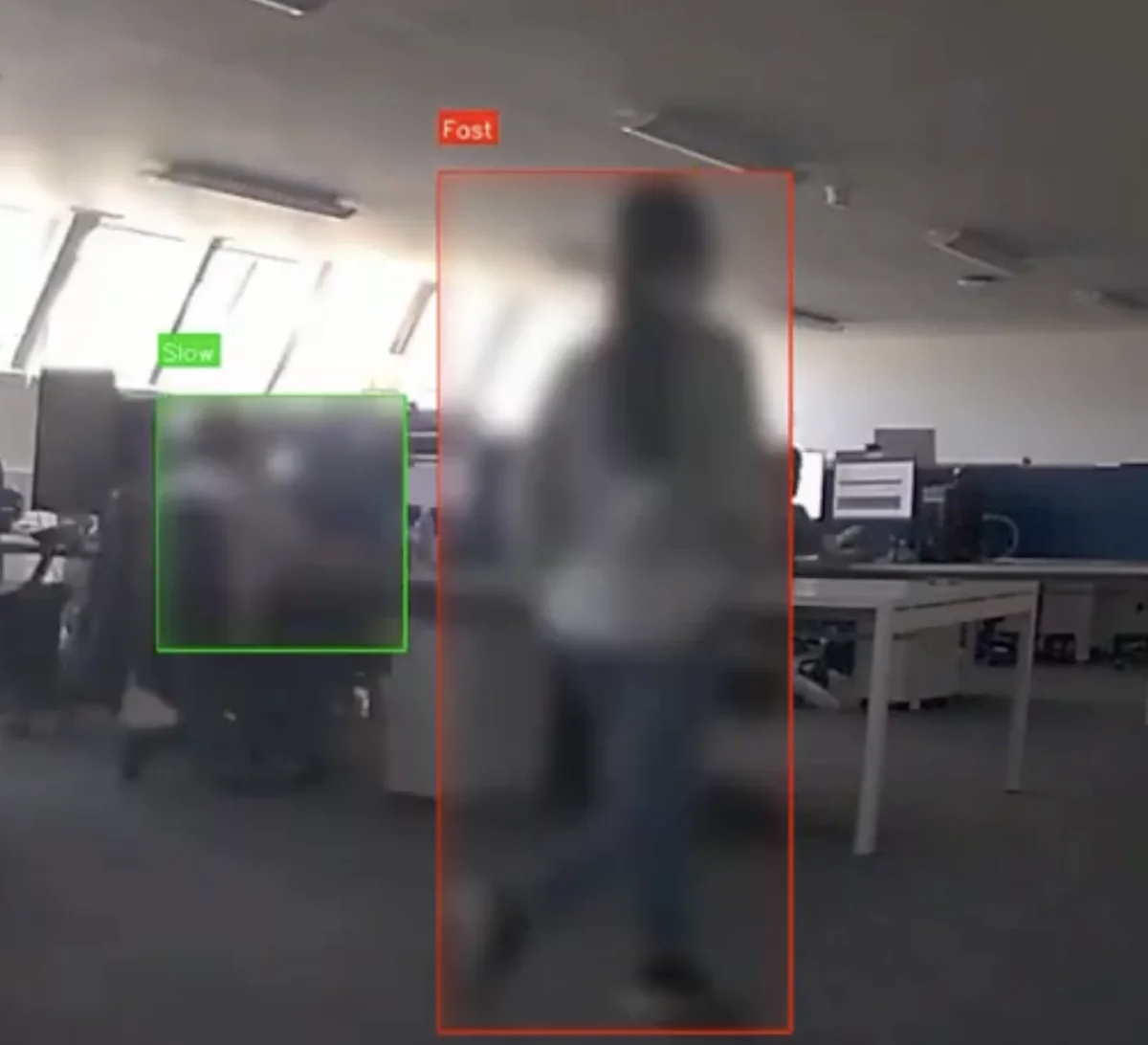

Human Actions Analysis - Videos

This project is a collaborative effort with Fennex Ltd to develop AI-driven solutions for proactive safety enhancement through video understanding. The core objective is to predict potential hazards by recognising and interpreting human activities in video data, enabling early anticipation of unsafe situations and supporting timely interventions in real-world industrial setting.

Read more →

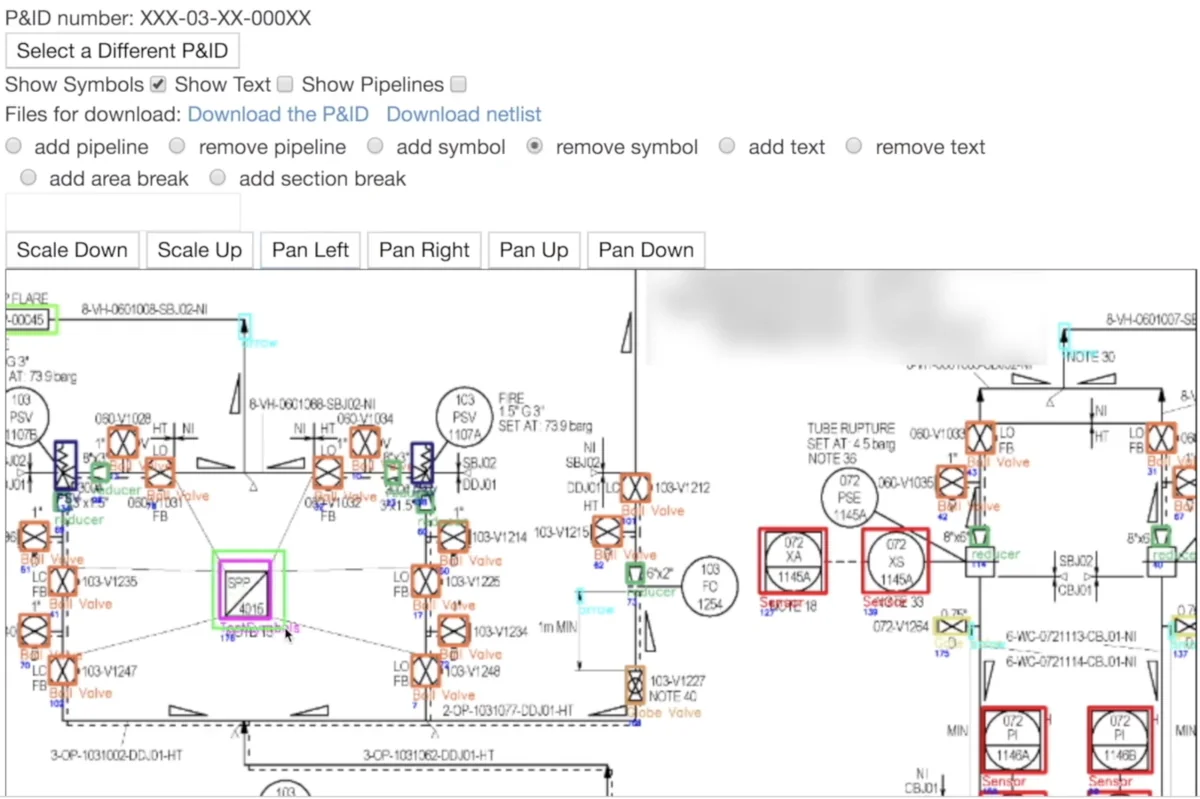

AI-Engineering Diagrams

Engineering drawings and diagrams are commonly used across different industries such as oil and gas, petrochemical, construction, transportation and others. Many legacy documents exist only as paper copies, scanned images or in pixelated format. Digitising these drawings is becoming increasingly important to enable conversion of information to a format which is compatible with other digital information relating to the same facility. In this ongong project we are developing an end-to-end solutions for processing and analysing Piping and Instrumentation Diagrams (P&IDs), Construction and electrical diagrams.

Read more →

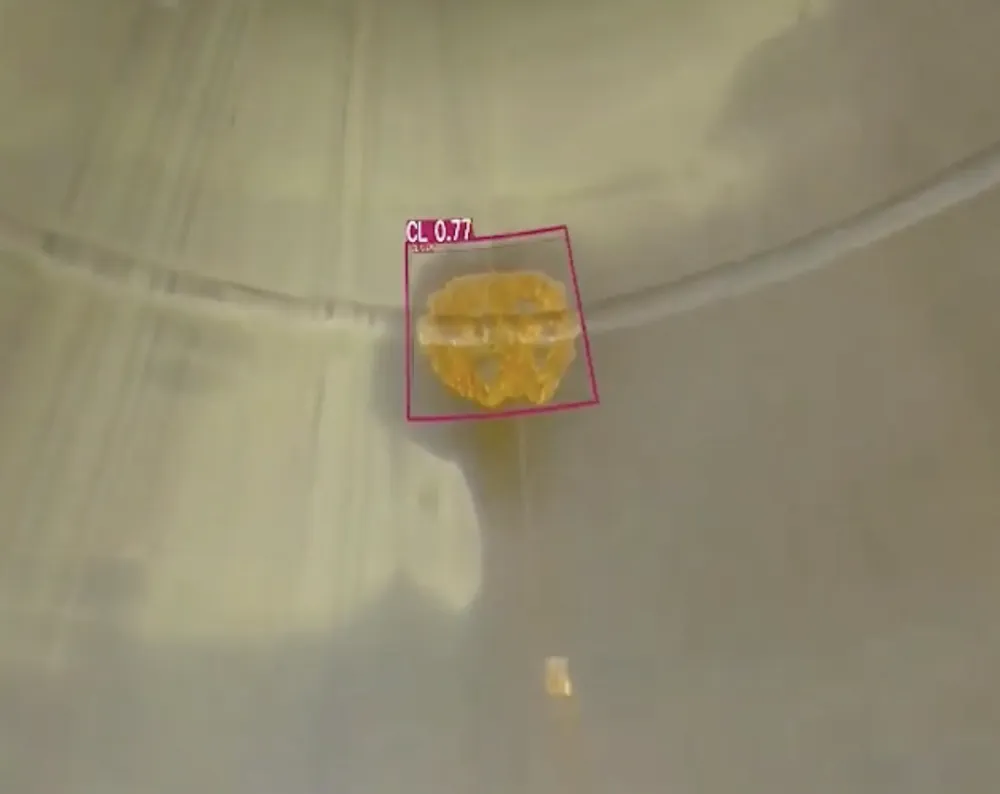

AI-Remote Inspection

This project focuses on developing AI-powered solutions for remote inspection of industrial assets and infrastructure. Using computer vision and deep learning, we enable automated defect detection, anomaly identification, and condition monitoring without requiring physical presence at inspection sites. This work included several funding bodies and industrial partners as shown below.

Read more →

Predictive Maintenance using AI

We have a strong track record in predictive maintenance, remaining useful life estimation, and asset health management for critical industrial systems. A representative example of our work is an AI-driven predictive maintenance solution developed for drilling equipment such as BOP annulars. The system combines machine learning, operational data, and automated visual inspection to assess asset condition and forecast failure risk. By analyzing usage cycles, days in service, pressure test results, real-time condition monitoring, and computer vision–based damage detection from inspection images, the solution enables condition-based maintenance decisions that reduce unplanned downtime, improve safety, and extend asset service life across drilling operations.

Read more →